Velocar – the key to mobility in a turbulent future

“Velocar” isn’t a sci-fi fad—it’s a sensible answer to everyday transport problems. We’re talking about a partially enclosed, three-wheeled vehicle powered by human effort (with optional electric assist) that offers a realistic alternative between a bicycle and a car. Motofocker’s Velocar development philosophy is refreshingly simple: rely on standard bicycle parts, steel industrial semi-finished goods, plywood, and canvas—everything that’s easy to source, shape, and repair, even in a garage.

Why switch to a Velocar?

Rural and suburban travel today is expensive, over-motorized, and time-sucking. The Velocar targets point-to-point trips: commuting, shopping, parcel delivery, workouts, and day trips. The semi-enclosed body shields you from blazing sun, rain/wind, and snow; the reclined/semi-reclined seat is comfy; and three wheels mean stability. Motofocker’s approach is pragmatic: no pricey composites or exotic alloys—just wood, canvas, and steel—lowering both manufacturing and environmental footprints while keeping production simple.

Velocar advantages (short version)

- • Classified as a “bicycle”: with pedelec assist up to 25 km/h, no driver’s license or taxes required.

- • Weather protection, comfortable seating, and three-wheel stability.

- • Standard components: easy repairs, easy parts supply, low running costs.

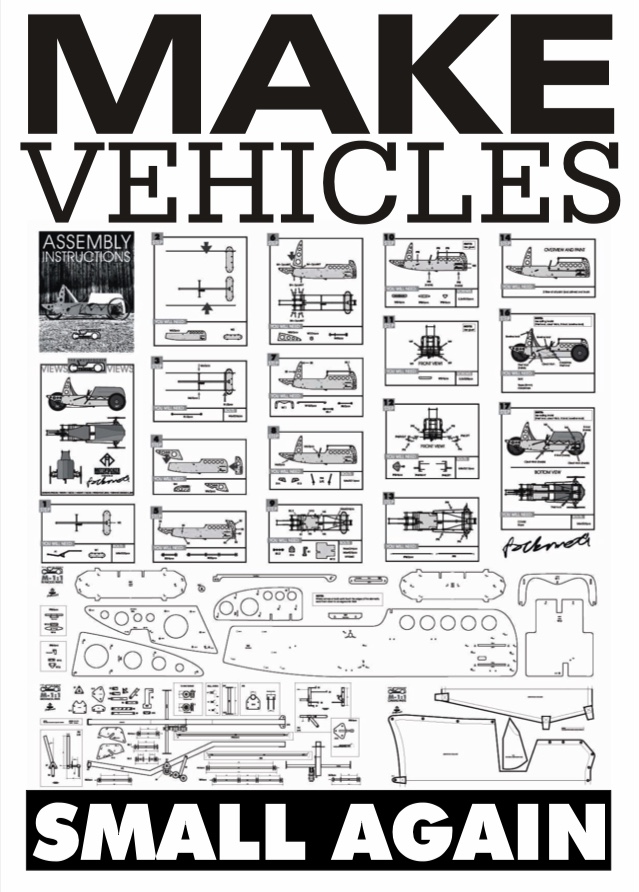

- • Modular, “flat-pack” mindset: home assembly possible with simple tools.

- • Low weight and aerodynamic shape: steady cruising with less energy.

Velocar drawbacks (honestly)

- • Three tracks: potholes demand more attention.

- • Harder to start on steep hills—electric assist helps a lot.

- • Wider and taller than a sport velomobile—but in return it’s roomier, more stable, and more visible, which also makes it safer.

Who is it for?

- • Suburban commuters who value predictable travel time and minimal upkeep costs.

- • Couriers/parcel deliverers who want cargo space plus protection.

- • Tourers who care about comfort, luggage capacity, and on-the-road serviceability.

- • People with musculoskeletal issues who need stability and a comfortable seating position.

Why materials and tech matter

From day one, the Velocar was designed not to depend on special, pricey, imported parts. Composites and exotic light alloys are indeed light, but they’re expensive, hard to repair, and equipment-intensive to produce. That’s why Motofocker chose wood, canvas, and steel: cheap, repairable, recyclable. The form follows this choice—flat-panel bodywork and parts you can work with hand tools.

Why so many velomobile projects fail

Podbike (Frikar)

In recent years, several flashy LEV/velomobile projects built on specialized components have hit the rocks. Podbike (Frikar) declared bankruptcy in 2025—reports point to complex engineering, high costs, and funding woes undermining mass production.

VanMoof

Not a velomobile, but still telling: VanMoof collapsed in 2023 after building a high-volume e-bike brand on a proprietary parts ecosystem—similar issues.

These are just two among many award-winning, genuinely pioneering startups with sad endings. The takeaway is simple: the more special components, pricey materials, and imported parts you use, the more fragile your business model becomes. That’s why the Velocar sticks to the “industrial semi-finished goods + bicycle standards” combo.

Why velocar fits the “Global South”, and why it’s cool in rich countries

Global South / developing regions: the Velocar can be assembled and repaired locally; no expensive production line needed. Wood-steel-canvas is accessible, and standard bike parts are available everywhere. This lowers FX/import exposure and supports micro-businesses (carpentry, metalwork, sewing).

Developed countries: the Velocar embodies “low-tech, high-logic” design culture: repairable, customizable, DIY-friendly, buildable in community workshops. It offers a working alternative for a third to half the price of premium sport velomobiles—less status symbol, more smart choice.

The designer and the research

Máté Fock, a designer with an art-industrial university background, has researched and developed the Motofocker Velocar since 2021. His goal from the start: design and prototype the world’s cheapest and easiest-to-produce Velocar. That meant excluding composites/plastics and light-metal alloys, and aligning the form, manufacturing methods, and supply logic with raw-material reality and user needs. The prototype was built with in-house resources and put through thorough testing.

What does “Velocar” mean today?

Many people mix up “Velocar” with “velomobile,” but Motofocker deliberately chose a different name: the aim isn’t a record-breaking, ultra-light sports device, but an accessible, repairable Velocar for everyday use. Historical precedents (Mochet Velocar) show that wood + canvas + steel is a proven, human-scaled combo even today.

The sensible alternative

Across Europe, over-engineering and one-off parts have sunk many transport projects. Heavy dependence on imported Asian components is another major risk. The Velocar takes a different path: standard, repairable, locally buildable (or globally obtainable) foundations—and pricing that keeps it from being a toy for the top ten percent. For anyone who sees sustainability not as marketing but as choices in materials and manufacturing, the Velocar isn’t a compromise—it’s the logical middle ground between a bike and a car.

Tags » velocar, velomobile

Sponsorship package

50 EUR

A/4 downloadable, home-printable blueprints and assembly instructions (pdf) with a thank you letter and one-time license.

Sponsorship package

extra

500 EUR

Downloadable and printable blueprints and assembly instructions (pdf) in M=1:1 size, with a thank you letter and one-time license. If you later purchase a kit or complete vehicle, we will credit 750€!

Be the first to know. Subscribe now and we’ll notify you when production starts. No spam, opt-out anytime.